Passive Fire Protection

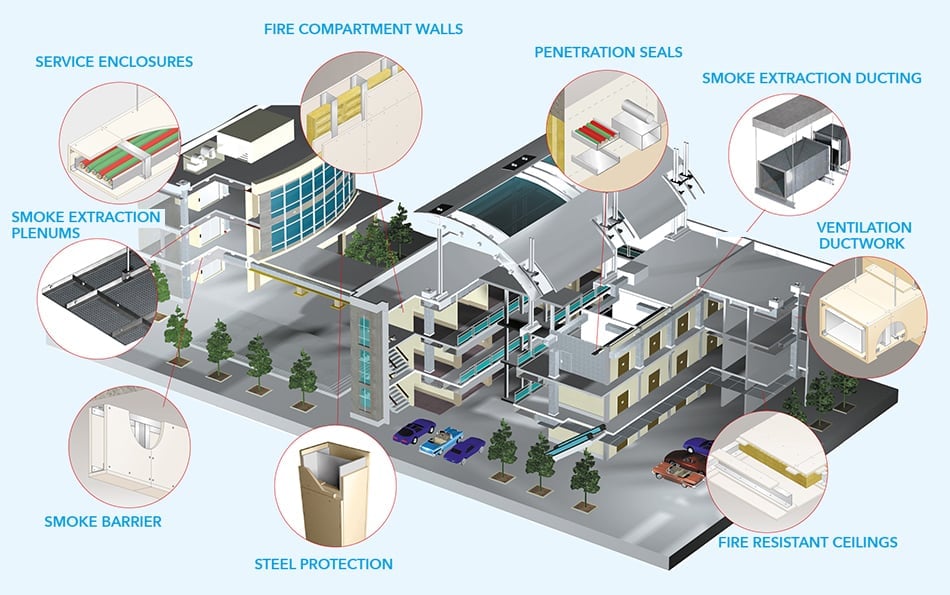

Passive Fire Protection is a group of system that compartmentalize a building through the use of fire resistance rated walls and floors, keeping the fire from spreading quickly and providing time to escape for people in the building.

Intumescent Fire Proof Coating

Thin film intumescent coating designed for the fire protection of steelwork for up to a 3 hour fire rating, depending on the steel design. The recommended use for this product is fireproofing of interior steel beams, columns, tubes, and pipes are typically used for structural steel in commercial and infrastructure projects such as bridges, commercial buildings, schools and airports. It can be solvent based or water-borne.

ACS Qatar offers expertise in the application of water-based intumescent paint systems that enhance the beauty of exposed steel structures while providing fire resistant upto 120 minutes as per BS 476 Part 21, upto 3 hours fire resistance as per ASTM E119, NFPA 251. The materials used provide a durable and decorative finish that can also be top-coated to match any aesthetic requirements.

- QCDD Approved Products

- B.S.476 Part 20/21

- Fire Rating Hours : 30,60,90,120 & 180 minutes

- Solvent & Water based Intumescent coating

- Approved by Warrington fire testing /Certifire

| Intumescent paints - efficient way of protection of steel materials against fire Intumescent coating, often referred to as intumescent paint, is one of the easiest and most efficient ways to protect load bearing elements of buildings against fire. Intumescent coating delays the collapse of the structure through insulating the structural elements (columns, beams, floors and roofs) that support the building, thus helping achieve fire resistance levels specified in terms of time. | Therefore it fulfills with the highest priority of passive fire protection, preventing the collapse of the building, allowing the time for safe evacuation of people from it, and making it safer for the emergency services and rescue team. Intumescent coating are an increasingly used way of providing passive fire protection to the load-bearing structures, especially structural steel, which is becoming more and more popular in modern architectural design of both industrial and commercial buildings. As a means of fire protection, it presents several advantages | Intumescent is a reactive coating which swells as a result of heat exposure, thus increasing in volume and decreasing in density. Specifically, an intumescent paint is a coating that reacts to heat by swelling in a controlled manner to many times its original thickness, producing a carbonaceous char formed by a large number of small bubbles that act as an insulating layer to protect the substrate. |

How intumescent paints work?

Intumescent is a reactive coating which swells as a result of heat exposure, thus increasing in volume and decreasing in density. Specifically, an intumescent paint is a coating that reacts to heat by swelling in a controlled manner to many times its original thickness, producing a carbonaceous char formed by a large number of small bubbles that act as an insulating layer to protect the substrate. The scope of intumescent products is the prevention of the structural collapse of the building, which can occur if load bearing steel elements reach a critical state.

Cementitious Fire Proof Coating (SFRM)

The technical name for Spray Applied Fireproofing is Sprayed Fire-Resistive Material (SFRM). It is used as part of a building’s passive fireproofing strategy. Spray applied fireproofing has thermal and acoustical properties and controls condensation. However, its main use is in insulating steel and metal decking from the high temperatures found during a fire.

Composition of Spray Applied Fireproofing

SFRM is composed of cement or gypsum and often contains other materials like mineral wool, quartz, perlite, or vermiculite. The gypsum or cement makes up the majority of the solution and is selected because it hardens as it dries.

ACS QATAR is an approved applicator for various passive fire-protection systems that include light-weight as well as high-density materials suitable for industrial and commercial requirements. The systems offered by ACS Qatar conform to the following international fire resistance standards

- QCDD Approved Products

- BS Std , ASTM E119 & UL 263

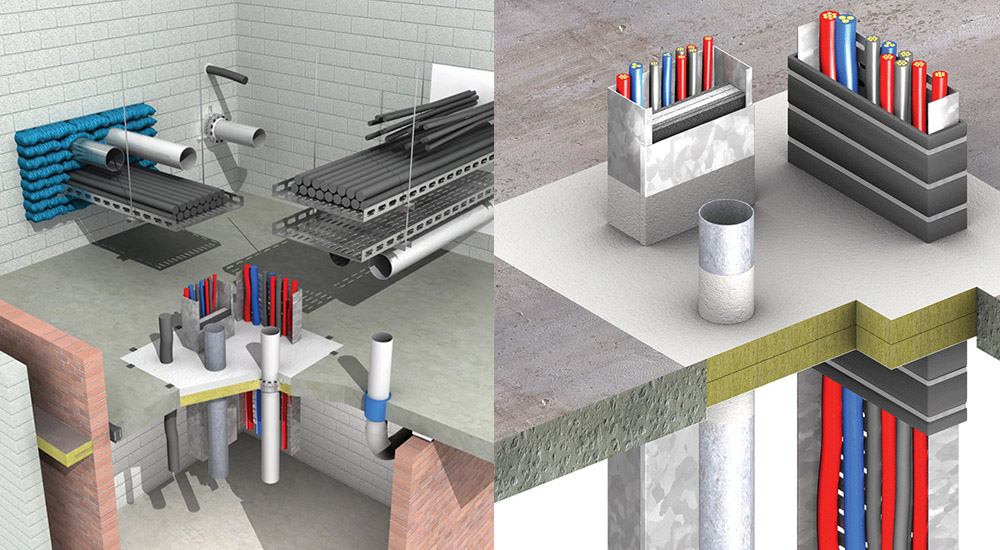

Fire Stopping

Fire-stopping systems are used to prevent fire in a particular floor from spreading to other floors. This is accomplished by sealing openings and joints through which fire could spread to other floors. Basically, there are four types of openings / joints to which tested fire-stopping systems are applied to prevent the spread of gasses, smoke and fire.

- Floor perimeters – slab edges and exterior wall cavities.

- Penetrations, including openings for mechanical, electrical, structural, security, communications, piping and wiring circuits.

- Openings with no penetrations.

ACS QATAR offers its expertise in installing effective fire-stopping systems in accordance with the manufacturers’ instructions. We can offer a full-fledged system to suit various requirements which includes fire-rated sealants, ablative, batts, fire-rated mortars, various board systems, collars, pipe wraps, expansion joints and linear gap seals.

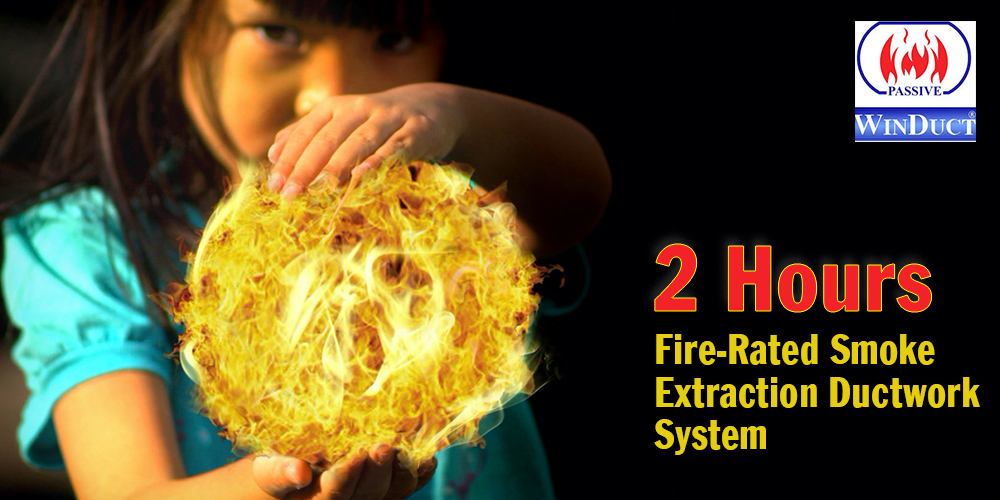

WinDuct

A fire rated ductwork system is designed to convey smoke, hot gases and flame from area to area, and to supply air combustion in the fire area. For this purpose and reason, it is essential to provide fire protection of a duct system to life safety and of course the protection of building and property.

The standard set by the fire department under Uniform Building By-Law is intended to prescribe minimum requirement are intended to:

The standard set by the fire department under Uniform Building By-Law is intended to prescribe minimum requirement are intended to:

- Restrict the spread of smoke through duct system in a building or into a building from outside.

- Restrict the fire through duct systems in a building.

- Permit the air duct system in a building to be used for the additional purpose of emergency smoke control.

- Ventilation duct systems intended solely for the evacuation of smoke, which are intended to maintain their integrity and cross sectional area within the fire compartment in order to enable maximum quality of smoke to be extracted throughout the fire period.

The WinDuct® system offers building consultants, architects and contractors an efficient way of designing ductwork for smoke spill and ventilation. It offers a 2-hours resistance to fire with the use of locally fabricated Galvanized Iron Ductwork improved with fire prevention coating. The system was tested with the Accredited Laboratory in accordance with International Standard and approved by the Fire Services Department. It was further tested locally and abroad to ensure that the WinDuct® system was suited to the local construction condition.

Application- Underground Car Park Smoke Extraction Ductwork System

- Kitchen Extract Ductwork System

- Pressurization Ductwork System

- Basement Ventilation System

Performance Criteria

All Fire Rated Ductwork should be officially tested to BS 476 Part 24 or AS 1530.4 with ISO Standard Fire Curve (ISO 834) of achieving stability, integrity and insulation performance criteria. It is further considered that any restriction of the cross sectorial area of Duct of 75% or less of its original area should be deemed to constitute failure.

Where required under the UBBL (Uniform Building By Law’s), the form of construction shall be constructed to that of the specimen that has been tested. Unless otherwise indicated, the fire rating shall be not less than the required for the construction separating the compartment.

VIDEO | MUTED.

For more details, Contact

Dominic Savio

Divisional Manager / Passive Fire Protection

Almoayyed Commercial Services

E. dominic@acsq.com.qa

O. +974 4434 0014

M: +974 5502 8241

G.I Duct Fire Proof Coating - Project References

Project . West Bay/Cornice Station - Doha Metro

Main Contractor . Duct Ventilation Air Conditioning Co.

Location . Doha-Qatar

Details . 5000 sq meter

Material . Wincoat

Project . Abraj Quartier Pearl Qatar

Main Contractor . Doha Climate Control

Location . Doha-Qatar.

Details . 22,000 sq meter.

Material . Wincoat.

Project . Wakra Stadium

Main Contractor . Midmac Contracting

Location . Doha-Qatar

Details . 9,000 sq meter

Material . Wincoat

Project . DCC/Al Qassar Station - Doha Metro

Main Contractor . Duct Ventilation Air Conditioning Co.

Location . Doha-Qatar.

Details . 5,000 sq meter

Material . Wincoat

Project . Hyper Market At Ezdan

Main Contractor . Al-Moayyed Air Conditioning

Location . Doha-Qatar

Details . 7,500 sq meter

Material . Wincoat

Project . Al Legtaifiya Station - Doha Metro

Main Contractor . Duct Ventilation Air Conditioning Co.

Location . Doha-Qatar

Details . 5,000 sq meter

Material . Wincoat

Project . Al Samariya Tower

Main Contractor . HBK Engineering

Location . Doha-Qatar

Details . 5,500 sq meter

Material . Wincoat

Project . Al Bidda Station - Doha Metro

Main Contractor . Duct Ventilation Air Conditioning Co.

Location . Doha-Qatar

Details . 5,000 sq meter

Material . Wincoat

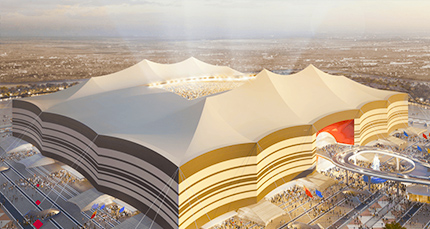

Project . Al Bayt Stadium

Main Contractor . Duct Ventilation Air Conditioning Co.

Location . Doha-Qatar

Details . 13,000 sq meter

Material . Wincoat

Project . HBK Head Quarters

Main Contractor . HBK Contracting

Location . Doha-Qatar

Details . 5,000 sq meter

Material . Wincoat

Project . Place Vendome Mall

Main Contractor . Al Moayyed Air Conditioning

Location . Doha-Qatar

Details . 2,000 sq meter

Material . Wincoat

Project . Majlis Grand Mercure Residence

Main Contractor . Al Ajjaj Limited Company

Location . Doha-Qatar

Details . 3,500 sq meter

Material . Wincoat

Project . HKH Tower

Main Contractor . Al Moayyed Air Conditioning

Location . Doha-Qatar

Details . 2,400 sq meter

Material . Wincoat

Project . Armed Forces

Main Contractor . Al Moayyed Air Conditioning

Location . Doha-Qatar

Details . 800 sq meter

Material . Wincoat

Project . New College Of Pharmacy

Main Contractor . Al Moayyed Air Conditioning

Location . Doha-Qatar

Details . 2,500 sq meter

Material . Wincoat

Project . Oryx International School

Main Contractor . Boom Construction

Location . Doha-Qatar

Details . 2,500 sq meter

Material . Wincoat

Project . Porto Arabia Parcel 7-B

Main Contractor . Al Moayyed Air Conditioning

Location . Doha-Qatar

Details . 1,500 sq meter

Material . Wincoat

Intumescent & Cementitiuos Fire Proof Coating - Project References

Project . Midmac Sixco JV Sports City Tower

Work . Basecoat and Topcoat for 2200sqm2

(Intumescent)

Location . Doha-Qatar

Material . NULLIFIRE S606 (Base Coat) NULLIFIRE

S616 (Top Coat)

Project . Sports City Tower

Main Contractor . Doha Climate Control

Location . Doha-Qatar.

Details . Cementitious fire proof coating 30,000 sqm2

Material . Pyrolite - 15

Project . Science & Technology Park

Main Contractor . Contrack International – Darwish

Engineering JV

Location . Qatar Foundation Doha, Qatar

Details . Basecoat and Top coat for 57,500 sqm2

Material . Intumescent fire proof coating

NULLIFIRE S605 (Base Coat)CARBOCRYLIC 3359

(Top Coat)

Project . Warehouse Facility in Ras Laffan

Main Contractor . Al Alia Trading & Contracting Company

Location . Ras Laffan, Qatar

Details . Basecoat and Top coat for 20,000

sq metre Intumescent fire proof coating

Material . PHOENIX – P168 (Base Coat) RAL 9010

(Top Coat)

Project . Landmark Ext. Carrefour

Main Contractor . Business Trading Company

Location . Ras Laffan, Qatar

Details . Basecoat and Top coat for 9,000 sqm2

Intumescent fire proof coating sq metre Material . PHOENIX P270-120 (Base Coat) RAL

9002 (Top Coat)

Project . GE Workshop

Main Contractor . Al Alia Contracting

Location . Zubara, Qatar.

Details . asecoat and Top coat for 9,000 sqm2

Intumescent fire proof coating sq metre Material . PHOENIX P270-120 (Base Coat) RAL

9002 (Top Coat)

Details

- Fire Protection ACSQ

- Date 29 March, 2020

- Category Fire Protection